Our xOptim suite offers a comprehensive range of advanced software tools designed to enhance efficiency, reduce costs, and optimize operations across the entire lifecycle of oil and gas projects. Each module is engineered with cutting-edge technology and tailored features to meet specific challenges in drilling, completion, production, reservoir management, cement evaluation, and plug & abandonment (P&A).

This module improves drilling efficiency by optimizing drilling parameters and workflows. It includes advanced capabilities for recognition and mitigation of invisible lost time (ILT) and non-productive time (NPT), while increasing safety to minimize risks and ensure reliable well delivery at lower costs.

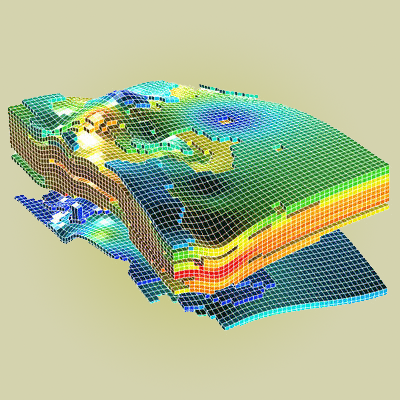

This module enhances evaluation of single-sector or multi-sector hydrocarbon reservoirs with advanced history matching of production data to estimate original oil in place, gas cap size, water influx and flow between sectors. Additionally, it enables future prediction of reservoir performance, empowering smarter decisions for optimized oil and gas recovery.

This module provides fluid characterization by modeling fluid properties under various pressure, volume, and temperature conditions, supporting better reservoir characterization, simulation, and improved production forecasting.

Designed to streamline and enhance a variety of completion activities—including completion string running, hydraulic fracturing, coiled tubing, and wireline operations—this tool focuses on reducing non-productive time (NPOT) and incidents of lost time (ILT), while increasing overall operational efficiency and effectiveness.

The production module leverages advanced production forecasting, network modeling, and artificial lift analysis to maximize hydrocarbon recovery and optimize surface facility performance, ensuring sustainable and efficient production management.

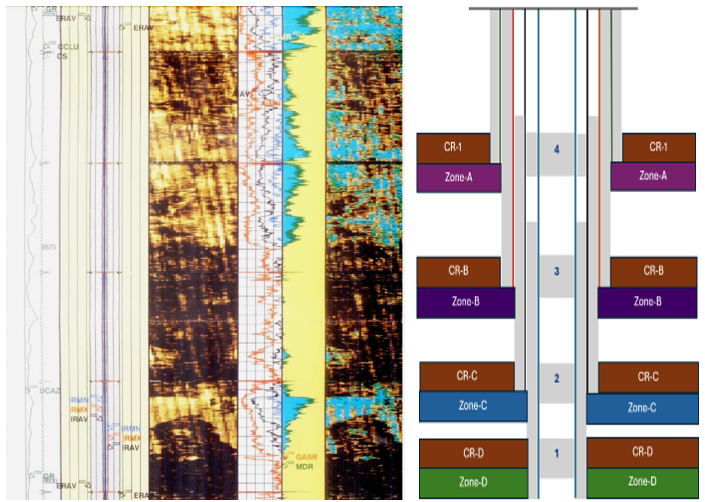

This module automates the evaluation of cement integrity in wells by integrating data from multiple sources such as logs, pressure tests, and cement bond evaluations. It ensures zonal isolation and well integrity, reducing the risks associated with poor cementing and enabling timely decision-making to avoid costly remediation.

This tool systemizes Plug and Abandonment (P&A) planning of non-activated or orphan wells by providing robust optimized design workflows, regulatory compliance tracking, and cost estimation, minimizing environmental and financial risks of such wells.

➤ Intelligent tools for real-time monitoring, performance prediction, and hazard recognition

➤ Smart Systems for minimizing non-productive time (NPT) and invisible lost time (ILT) and reducing costs and greenhouse gas emissions

➤ Tools for well control and operational safety maintenance via early kick detection and automated decision-making

➤ Data-driven design and execution of hydraulic fracturing (fracking), wireline, and coiled tubing operations

➤ Optimization of stimulation treatments, zonal isolation, and perforation strategies

➤ Smart analysis of artificial lift systems, flow assurance, and production performance

➤ Focus on minimizing NPT and ILT during completion and production

➤ Reduction of downtime and interventions through intelligent diagnostics and real-time surveillance

➤ Integrated and intelligent workflows for reservoir forecasting and scenario planning

➤ High-accuracy PVT modeling and fluid characterization to support recovery strategies

➤ Optimization of enhanced recovery techniques and sustainable reservoir management

➤ Application of simulation and engineering design principles to petroleum and geothermal reservoirs

➤ We offer cement evaluation using sonic and ultrasonic cement bond logs, well integrity tests, sustained casing pressure analysis, temperature noise, fiber-optic logs, and other diagnostic tools.

➤ Our plug and abandonment services include detailed procedure design with step-by-step execution, specifying cement plug locations, characteristics, and compliance with industry standards.